It usually starts with a faint smell of fish or burning plastic in the garage. For others, it’s a tripped breaker that feels hot to the touch. In the worst-case scenarios, it is a blackened, fused lump of plastic where your charging cable used to be.

There is a silent epidemic occurring in garages across the country: EV charger outlet melted scenarios are becoming terrifyingly common.

If you drive an electric vehicle and charge at home using a standard plug, you need to understand that your house wasn’t originally built for this. This isn’t a fear-mongering post; it is a forensic safety analysis of why standard electrical parts are failing under the unique stress of electric vehicle charging—and exactly how to prevent it.

The “Dryer Outlet” Myth: Continuous vs. Peak Load

The root of the problem lies in a fundamental misunderstanding of electrical loads. Most new EV owners are told they just need a “dryer outlet” (technically known as a NEMA 14-50) to get Level 2 charging speeds. They go to a big-box hardware store, buy a receptacle for $10, and have it installed.

Here is the forensic reality: That $10 outlet was never designed for an EV.

Standard residential receptacles are built for electric ranges and dryers. A dryer might pull 30 amps, but it cycles on and off. It runs for 45 minutes and then cools down. It rarely runs at full capacity for hours on end.

An EV charger is different. It pulls high amperage (often 32 to 40 amps) continuously for 6, 8, or 10 hours straight. In the electrical world, this is called a continuous load. This sustained draw creates heat—lots of it. If the outlet has even a microscopic amount of resistance, that heat builds up, creating a “thermal runaway” event that melts the plastic housing.

Residential Grade vs. Industrial Grade: The Hardware Gap

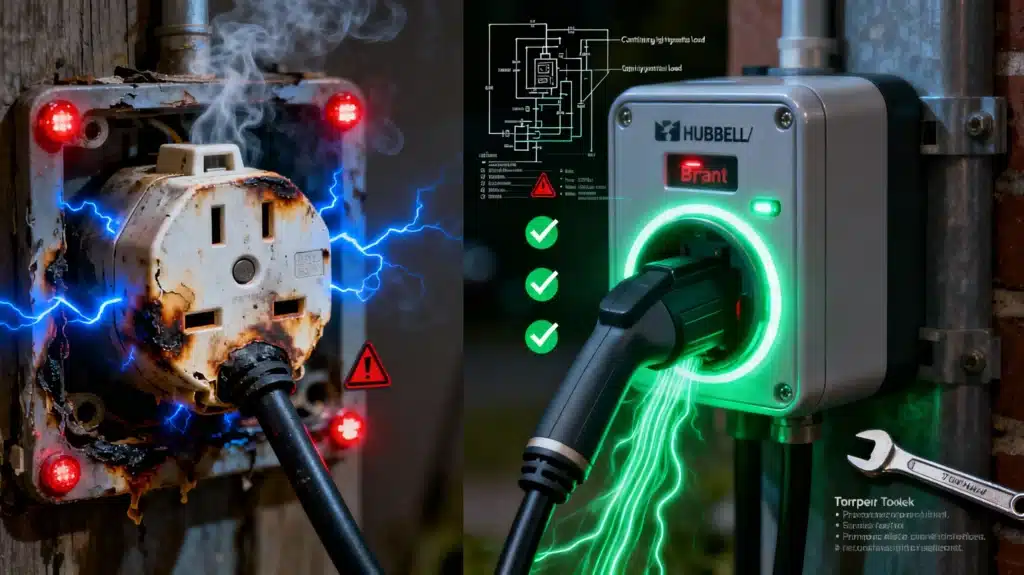

When we analyze melted outlets, we almost always find they are “Residential Grade” parts. These are the affordable receptacles you see on the shelves of general hardware stores.

To ensure dedicated circuit EV charging requirements are met safely, you must understand the physical differences between these grades:

- Residential Grade (The $10 Part): These often use a plastic body and steel contacts. Steel is less conductive than brass, meaning it generates more heat. Furthermore, the internal clamps are designed to hold a plug that is plugged in once and left alone for 10 years (like a stove). They are not designed for the daily plugging and unplugging that EV drivers do.

- Industrial Grade (The $50+ Part): Brands like Hubbell or Bryant make industrial-grade NEMA 14-50 receptacles. These are heavier, bulkier, and made of high-heat composite materials (phenolic/thermoset) rather than standard thermoplastic. Inside, they use massive brass contacts that grip the plug blades with significantly more force.

The Takeaway: The extra $40 you spend on an industrial-grade receptacle is the cheapest insurance you will ever buy for your home.

The Invisible Enemy: NEMA 14-50 Torque Specs

Even if you buy the best industrial outlet on the market, it can still melt if installed incorrectly. The second most common cause of failure is improper torque.

Electricity causes wires to vibrate slightly. It also causes them to expand (when hot/charging) and contract (when cool/stopped). Over months of charging, this “thermal cycling” can wiggle a wire loose if the screw terminal wasn’t tightened to the exact manufacturer specifications.

A loose wire creates an air gap. Electricity arcing across that gap creates intense heat (thousands of degrees), which melts the terminal and the wire insulation.

Why “Hand Tight” Is Dangerous

Professional electricians use a torque screwdriver to tighten these terminals. The NEMA 14-50 torque specs for high-quality outlets are often very high—sometimes up to 75 inch-pounds. This is difficult to achieve with a standard handheld screwdriver; it feels like you are overtightening it, but you aren’t.

Without a torque screwdriver, the connection is likely too loose (causing arcing) or too tight (crushing the wire strands and reducing current flow). Both lead to melting.

Hardwiring: The Ultimate Safety Fix

While upgrading to a Hubbell or Bryant receptacle is a massive improvement, the safest method for Level 2 charging is to eliminate the receptacle entirely.

Hardwiring your wall charger means connecting the unit directly to the electrical wiring in the wall, bypassing the plug and outlet connection. This removes the “weakest link” in the chain.

Hardwiring offers two distinct advantages:

- Zero Thermal Points: There is no plug to wiggle loose or outlet contacts to oxidize.

- GFCI Compatibility: Modern electrical code requires plug-in outlets in garages to have GFCI protection. However, EV chargers have built-in GFCI. Sometimes, these two protection systems conflict, causing “nuisance tripping” where your car stops charging for no reason. Hardwiring bypasses the need for a GFCI breaker in most jurisdictions, solving the tripping issue and the melting issue simultaneously.

For a deeper dive into setting up your station, refer to our guide on Charging Infrastructure.

Summary: How to Charge Safely

If you are installing a new circuit or inspecting an old one, follow this checklist to avoid the melting epidemic:

- Demand Industrial Grade: explicitly ask your electrician for a Hubbell HBL9450A or Bryant 9450 receptacle. Do not accept generic “big box” substitutes.

- Verify Torque: Ensure the installer uses a torque tool to meet the specific NEMA 14-50 torque specs listed on the device.

- Consider Hardwiring: If possible, skip the plug and hardwire the unit.

- Monitor Heat: Occasionally touch the handle of your charger plug after 2 hours of charging. It should be warm, but never too hot to hold.

Frequently Asked Questions

Why did my EV charger outlet melt?

It likely melted due to high electrical resistance caused by a “residential grade” outlet that couldn’t handle the continuous load, or because the wire connections were not tightened to the correct torque specifications.

What is the best NEMA 14-50 receptacle for EV charging?

Forensic analysis consistently points to Industrial Grade receptacles as the safest option. The Hubbell HBL9450A and Bryant 9450 are widely regarded as the gold standard for their ability to handle the heat and stress of EV charging.

What are the correct NEMA 14-50 torque specs?

The torque specifications vary by manufacturer, but industrial-grade outlets typically require between 70 and 75 inch-pounds of torque. Always check the side of the receptacle or the manual for the exact number and use a calibrated torque screwdriver.

Can I use a dryer outlet for my electric car?

Physically, the plug fits, but standard dryer outlets are often not robust enough for the continuous, high-amperage draw of an EV. If you use an existing dryer outlet, ensure you lower the charging amperage in your car’s settings to reduce heat build-up.

Do I need a GFCI breaker for a NEMA 14-50 outlet?

Yes, strict adherence to the latest National Electrical Code (NEC) usually requires GFCI protection for outlets installed in garages and outdoors. However, this can cause nuisance tripping with EV chargers. Hardwiring the unit often removes this requirement.